The phenomenon known as concave wheels has changed the wheel game forever and has become the newest trend in aftermarket wheels worldwide. Replacing the classic but outdated look of the typical lips on wheels, concave wheels gives a car the ultimate depth in looks while maintaining all the functionality of the original aftermarket style wheels. We are now witnessing this concave style quickly becoming a new industry standard but do we ever wonder where the concave wheel came from?

We take a moment to speak to the creator of the concave wheel concept and see how an idea drawn on a napkin during lunch became the world’s newest and best selling wheel design.

Jordan Swerdloff, founder and owner of ADV1 Wheels has had his shares of ups and downs and many have heard his rise to the top is nothing short of impossible. One thing remained certain for Jordan, his drive and passion to one day revolutionize the wheel industry lives on. He takes a moment to share with us some interesting insight about his awe inspired concave creation and gives us a lesson on how an idea is useless without proper execution.

I heard that you had the first concave design drawn on a napkin? Can you tell me about that?

This is true, I had been thinking about designing some sort of concave profiled forging for some time and had this idea to combine a concave profile with a deep lip. This was back in 2007, we didn’t really have any real knowledge of engineering or resources to do anything like that but I thought it was a great idea and I knew that it needed to be done one way or another. I was at a lunch meeting with a couple guys who I won’t name and I drew the forging profile on a napkin to discuss the possibility of getting it engineered and manufactured. At the time, the idea was pretty far out there so I got the typical “it’s impossible”, “why?”, etc. So I left it at that for the time being, knowing in my head that I’d get it done anyways. I’m like the terminator when I get an idea in my head, no matter what it’s gonna get done.

What did you do after you came up with the design? Why did you think it would be a hit?

Once I finalized the design with my 3d artist and threw some renderings together it was obvious, the look was absolutely amazing – especially being that at that time there was nothing else like it ever seen. I see it now and I feel like it’s old already but at the time it was the first thing to change a 3 piece wheel in years and possibly the most significant change ever. Back then it was 360 obviously, not ADV.1 so after tweaking the design and renders for a couple weeks I released them online just to gauge the reaction. Never to this day have I seen such a huge response from any development I’ve ever been a part of. It was pretty amazing, but they were just renders – although I made sure to make them as realistic as possible as far as fitment and final design, they were still renders and not in production, nor did they have any production date in sight. Releasing those renderings was a huge mistake, at the time it was great – since the company was in trouble it gave us some hope and created a good buzz, but the downside was that it started the concave race and gave competition the opportunity to start on development before I had anything in production.

Regardless, these things take time and I knew that just like them, I was pushing to make this happen and I knew that not only would it be done first, it would be done right and look right. From then on, while the development of ADV.1 was underway, so was the deep concave forging and sure enough by late 2009 – months before the rest, it was finally ready.

How long did it take you to go from idea to product?

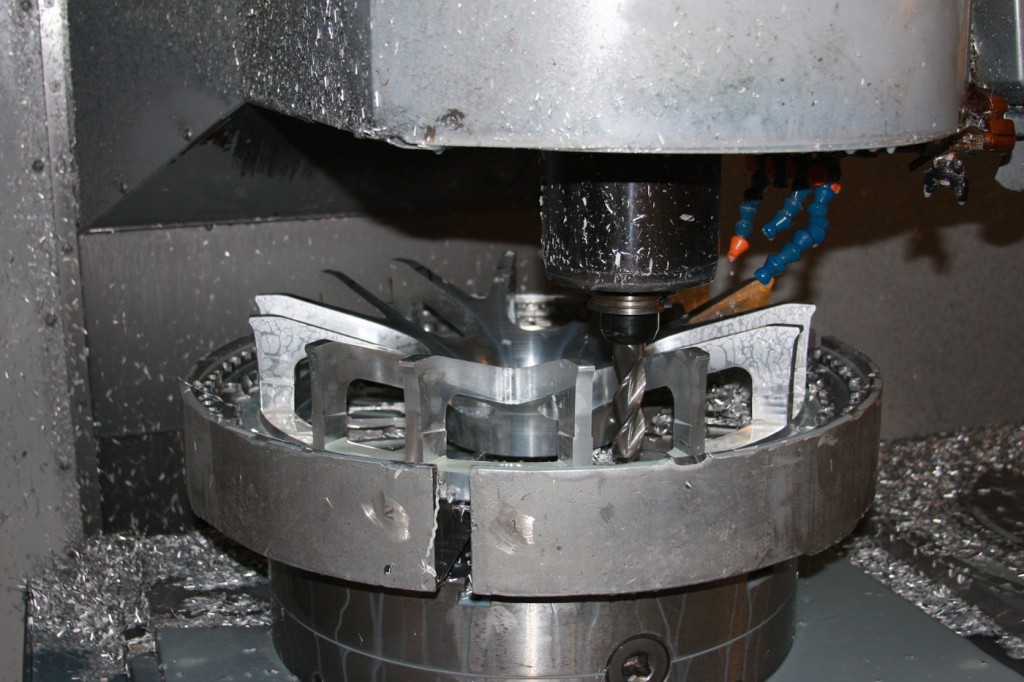

I’d say about 6 months from idea to early renderings, and another year before it was in production. Something like this takes time, not for the guys who copy it – but for the initial development. From a drawing on a napkin to a 3d model is a relatively quick process, but the real engineering and forging development is very time consuming and detailed. You have to keep cost down by designing a raw forging with minimal waste material, while at the same time it needs to have enough material to remain versatile and usable on a lot of different applications. Our forging weighs a ton, but it’s capable of so many different applications and configurations unlike other copies. The forging also needs to go through a testing process which takes time and requires test pieces to be made from billet which is another process. After all that the mills need special tooling, new programming, etc. The entire process is very in depth, time consuming and expensive – and that’s all for only one diameter in only one variation. We have fronts, rears, and diameters 19″-24″. It’s a huge project, but as you can see the end result has been amazing and is now used by nearly every manufacturer in the wheel industry.

It seems that ADV1 only offers concave applications? Are you that confident that the concave wheel is here to stay?

We actually offer profiles in flat or semi concave configurations as well, our forgings are engineered for versatility so we’re not locked into a specific profile – it’s more expensive but allows us to offer such a wide range of choices. The trends in the wheel industry change, but they change when someone creates a new trend and leads the market in a new direction. The big lip craze was the standard for years, and all of a sudden it all changed and the new standard is concave depth. The trend will keep evolving and yes, eventually the standard in wheel design will be something different. I’m not basing ADV.1 on following a trend and riding the wave until it’s done with, ADV.1 created this trend and we’re the ones evolving it. Not to sound arrogant but we’re undeniably changing and reshaping the standard in wheel design for the entire wheel industry to follow, and they are. We’ll continue to evolve and the styles will continue to change, but the question isn’t “is the concave wheel here to stay?” it’s “when will we decide it’s time to close that chapter and move on to the next standard?”

What was the most challenging aspect of doing something that had not been done before?

It’s difficult to go from idea to reality. Like any development, it takes alot of drive and ambition to push something to get done despite the obstacles and setbacks. That’s probably the hardest part. Lot’s of people have great ideas every day, but barely any of them actually make something happen. I’m a firm believer of the saying “when there’s a will, there’s a way” because it’s true. If you want to get something done, and you force yourself to move forward regardless of any complications, eventually you’ll get it done. I’ve developed lot’s of products and things that hadn’t been done before since I was a teenager and that’s always been the hardest part.

Something I’ve learned after going through so many projects and ideas, some good and plenty bad, is that you can’t force motivation and you can’t force an idea. Ideas come and go but every now and then you’ll have an idea that you know is something special. It’s not something you can try to come up with, it just happens sometimes. The motivation and drive to pursue it is either in you or it’s not and unfortunately you can’t force it. I feel fortunate that I’m ambitious enough to follow through with developments that I believe in, I know it’s not easy and I’ve watched other people go through the process of trying and giving up many times – my only advice is to follow through no matter what if you really want to make it happen.

Were there any glitches that made you feel like maybe this was bad idea?

No, not at all. It’s just metal, you can engineer and make anything you want, it’s just a matter of getting it done and evolving the design until it works. If I ever felt any doubt in an idea I wouldn’t waste my time on it, but when I’m sure about it I can guarantee that it will get done regardless of any obstacles. I’m not saying that every idea that I come up with is successful at all, I’m just saying that if it reaches the point where I want to start something, I’ve already made up my mind and weighed out any possible glitches before hand.

How do you feel about the fact that others have now fully integrated your concept in their wheel lines?

I’m not upset about it, I understand that it’s always going to happen. In a way they have to, it’s now what people want and if you don’t offer it you lose the sale bottom line. I personally wouldn’t copy anyone’s trend, but most companies don’t care – they’re in business based on making what people want, not creating what the people will want next. I have a lot of respect for the few companies that haven’t copied us, I can imagine that it’s hard for them to make that decision especially if it’s what’s in demand. They’ve sacrificed sales in order to not fall into that category and that’s commendable. I would do the same. Now that I’ve had design after design copied, I’m much more careful about protecting the developments and thankfully we’ve proven ourselves to the point that we’re able to develop anything we can think of with the full support and exclusivity from our suppliers as they know by now that we know what we’re doing and our products sell. Any future developments are protected and although anything can and will be copied, it takes time and by the time our competition offers it we’re well into the next project.

Any plans to revolutionize the industry in 2011 once more?

Without getting into detail, I’ll leave you with this: YES, the developments that we’re working on will again change everything. ADV.1 is constantly evolving, new ideas and design changes are happening every single day. I won’t go on about our plans and ideas, just sit back and watch : )

Thank you to Jordan Swerdloff for sharing the concave story with us and schooling us on business and execution. For those of you that have not had a chance to look at the world’s sickest cars and sickest wheels, make sure to check out ADV1 Wheels and find out what all the fuss is about. Make sure check out the gallery on their site.